Interview with Cervelo's Phil White

Wandering through the expo in Kona this year, I quickly realized that there isn’t much new in the world of tri bikes. One of the few exceptions is Cervelo’s flagship P5 which made its Kona debut, racking up 2nd under Caroline Steffen and 3rd under Frederik Van Lierde, not to mention top 10’s from Amy Marsh and David Dellow. Even the “antique” P3 was ridden to a 5th place by Mary Beth Ellis. I had the opportunity to sit down with Cervelo co-founder Phil White to get the inside scoop on the P5 and other things aero.

Phil is clearly passionate about his products -he is in Kona every year, spending most of the week prior to the race baking in his booth at the expo, talking with all comers about his bikes. On Friday he is out there at the bike check-in cheerfully tossing t-shirts and well-wishes to any athletes wheeling Cervelos – no matter how old – onto the pier. I saw more than one P2k go in. It was clear that many of these athletes had no idea who Phil was – even if his name is on the chain stays of their bikes. But they all clearly liked their Cervelos, and Phil expressed his genuine gratitude to one and all Cervelo riders as they prepared to enter the transition area.

TK: Phil, lets start a few years back when you began looking towards your next superbike design. What were some of the major improvements you were looking to make over your existing line and what competitors had to offer?

PW: When we did the P4, we started looking at how athletes actually use the bike. We looked at hydration. We found that a big gusset above the bottom bracket was good for aero, and if you put hydration there you could take something that normally adds drag and instead reduce it. This was the first time this had been done. But we found that riders didn’t like drinking out of that bottle; they mostly used it for storage. So we learned from that. We realized we shouldn’t drive the way the athlete uses the bike – we should offer a selection of solutions that in each case actually make the bike faster whereas they traditionally make it slower. So that was one goal.

Another issue was when the P4 came out, wheel manufacturers surprised everyone in the industry with wide profile rims that in many cases were incompatible with existing frame and brake designs. We had been designing for the same wheel specs since the 90s, and now we had something new. And with the P4, and I take some responsibility for this, we were so focused on making it faster – we made the rear brake disappear so that it generated no drag. But, it didn’t brake well, was difficult to set up and adjust, and didn’t work with the new wheel designs. So we stepped back and said, “hey, a brake needs to stop the bike – its not an acceptable tradeoff to sacrifice that for aero.” But we started a trend, and then we had the whole industry taking this to a greater extreme than we did. You had bikes where the cable routing was kinked in low stem positions. You had bikes that took 45 minutes just to set up the brake when you unpack it at a race. And then you may still need a trained mechanic. So the whole industry failed the athletes.

So we looked at the P5 from the viewpoint of the end user. We wanted to offer a variety of hydration, nutrition, and storage options that make the bike faster. Of course the bike had to be faster than what was out there – that’s what we’re all about, but it had to serve the athlete well in real life.

TK: Are you at the point where though where it is getting nearly impossible to make a bike faster?

PW: Well everyone always says that and asks where can you go now, yet we continue to make big leaps in performance.

TK: So that brings up the guy with a tricked out P3: he’s fit on it well, has some really nice bars on it, maybe aero brakes – is it worth it for him to jump up to a P5?

PW: Yes! We don’t bring out something just to bring out something new on a schedule. The P3 was hard to improve on, it is still a great bike. But we bring out something new if it is much better. The P5 is a significant step forward. Plus we have a much larger fit envelope than the P3.

TK: Right, I’ve run it through my fit calculators and you can get a broad range of fits on that bike.

PW: We wanted to make it fit higher than the highest P2 and lower than the lowest P4. So our integrated bar choices make this possible with one head tube height whereas we had the two different ones on the P2 vs P3/4 (note: in bigger sizes only).

TK: Plus there is a version of the frame where you can use a conventional stem and bar setup…

PW: Well sure you can do that on any P5 – the frame is the same for the 3 and 6 versions. They have a conventional steerer. The 6 model comes with the 3T Aduro front end, but you can still use a conventional setup if you like, at some amount of aero cost. But it does have the advantage of two price points. It is modular, so you can add on all the upgrades to the 3 over time if you like – front end, brakes, etc. The Aduro bars accept the standard 22.2mm extensions – so you can use any extension you prefer. It has a collet lock for the extensions, so it is very adjustable. We really wanted to make this bike easy to adjust, and wanted it to be easy to set up in the best position for a particular rider.

TK: Along those lines, two of your competitors have recently announced fit system acquisitions – where do you come out on that?

PW: Well we offer products with a wide range of fit options, and we don’t feel it is our duty to tell our dealers how to fit the athletes. There is a variety of different philosophies and systems, some work well for some folks, others work better for others. We provide the data that dealers need to fit, and let them decide how to do it. As long as we provide our dealers the necessary data, like stack and reach, they can apply it to whatever fit method they choose. It used to be that one guy’s 56 was another’s 58…

TK: Right – that’s what I do all day, interpreting fit dimensions and matching them to riders. But the advent of stack and reach has been a great way to standardize fit in tri bikes. Not so much the stack and reach of the frameset, but where the front end of the bike can actually end up.

So getting into more details on the P5, I do encourage those so inclined to read your 38 page P5 whitepaper on the website (which I really enjoyed). But let’s hit on a few details. One way to adjust the fit is a set of aero shaped steerer spacers, up to 5.5cm, that raise the stem and match the stem’s shape. You state that unlike with round spacers, this can be accomplished at no aero deficit. The question I have is that the back end of the stem and spacers is flat (as opposed to tapering like an airfoil) – so I would think a stack of these would in fact add drag? One of the CFD diagrams in the whitepaper (which show areas of high and low air pressure as air flows past the bike) seems to indicate an area of low pressure behind the stem/spacers, which would cause drag.

PW: Well that was the reason we designed it together with solutions on fuel – there are two bolts on the top tube behind the stem for storage – Torhans makes something, Dark Speed makes one, and I guess X-Lab has several different heights of fuel boxes to match your stem height. The Torhans one is probably the least drag, but the X-Lab version allows the most configurations. So we designed it from the beginning to have a fuel box in this location – that’s why the stem and spacers are truncated.

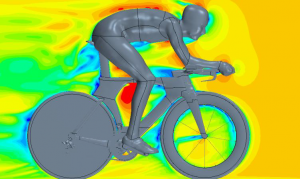

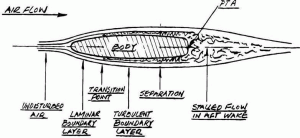

TK: Looking across the superbike offereings in the industry right now, you see a wide variety of “tube” shapes – some use truncated airfoils or “Kamm tail” sections, others use more traditional airfoil shapes or varying aspect ratios. You guys use a mix of shapes – most of the P5’s “tubes” are traditional airfoils, but for example the top of the seat tube uses a truncated shape. I was interested to see in some of the CFD (computational fluid dynamics) diagrams that this creates a low pressure area that actually helps pull flow down around a rider’s back – prevent the flow for detaching early and causing more drag.

PW: Yeah you’re right – that’s kind of neat. Each airfoil on that bike is tuned to what we define as aero zones. The front of the bike sees very clean flow, so a nice traditional airfoil shape works really well. As you get closer to and then behind the rider you have interactions with the rider, which we know causes 80% of the drag, so you will have huge effects. So we designed something that would work well with a rider there. And that area of truncation on the back of the seat tube – if you look at the CFD you see a blue stripe, or negative pressure area – which sucks flow down from other areas. It’s not huge, but it’s every little thing like that, it’s all these details that make this bike faster than the last generation of bikes. So every zone now has an airfoil that’s designed to work in that particular flow regime.

TK: And this all works well out into broad yaw angles (crosswinds)?

PW: Yeah it’s still designed to work well out beyond 20 degrees. Everyone says Kona is different, you have lots of high yaw, but the P5 is still a significantly faster bike in Kona conditions. It’s designed for a wide range of yaws.

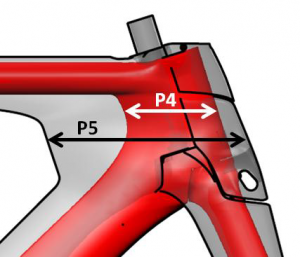

TK: Now, in the head tube and seat tube areas you clearly have airfoil sections that are higher aspect than the UCI’s maximum allowable 3:1 ratio – how did you get around that rule?

PW: If you look at the UCI rules, they say basic airfoil tubes can’t be greater than 3:1 aspect ratio. But then they say you can use gussets, and they can be any shape. So now you use the 3:1 head tube as the nosecone of the airfoil, and the 3:1 gusset as the tail, and you have a 6:1 airfoil that’s totally legal. Some said we stretched the rules, but no – it’s totally legal as they are written.

TK: Until they change the rule the day before the Tour next year…

PW: Grrrr… it is what it is. But by putting the brake out front, we actually get an airfoil bigger than 6:1 when we add the brake cover for triathletes.

TK: Because the brake cover acts as the nose of the foil.

PW: Right – so triathletes get a better airfoil with this non-integrated brake than you would with a user unfriendly integrated brake. The roady, who must use the UCI-legal fork, still gets a much more aero setup with that small streamlined brake out front than he would with another type of setup.

TK: Some of the other manufacturers have been touting non-UCI legal, triathlon-specific bikes. So they might have, for example, down tubes with 5:1 or greater airfoils. Clearly Cervelo has a big Pro Tour presence. Do you look at the P5 and think that if you didn’t need to follow UCI rules, you might have done something different?

PW: Well the nice thing with using CFD, when you go to the next level and start using it as a design tool instead of just to have someone make a diagram for your brochure, you really start to understand what’s happening with the air flow on the bike. You don’t learn that as well in the wind tunnel. So that was the advantage of hiring a full-time aerodynamicist. You know we have a PC in house with 16 processors and access to a super computer running 256. So we run all these analyses and what we found out is the down tube, we wouldn’t change it. It is perfectly dialed for the flow regime there. So with CFD we can really see where the gains come from.

TK: So going back to truncated airfoil designs, which are now being used on several superbikes, in your CFD diagram you can see low pressure, or drag, behind your truncated seat tube. But the guys who use these foils all over their frames say that doesn’t matter, because the flow “thinks” there is a tail there. So therefore you can design a tube to “act” like it is a longer airfoil than would be practical (or legal) to build out of carbon. So then why aren’t truncated airfoils the way to go?

PW: Well if that was true you’d have airplanes with half-wings. It’s obviously not as good as a complete airfoil – I think people are starting to understand that now. Our philosophy was truncation where it makes sense. Obviously one place it makes sense is in front of the wheel.

TK: The wheel acts as the tail of the foil.

PW: Right. And the other place, on the seat tube behind the rider, is nothing like a clean air flow situation. It is specific to the flow regime there.

TK: Talk about your concept of skin surfaces.

PW: We stopped looking at the bike as a collection of aero tubes blended together, like our competitors do. We look at the frame as skin sections blended together and designed to fit specific flow regimes.

TK: Where is the P5 manufactured?

PW: This bike is meant to be sold in volume, so it is made in China.

TK: What can you tell a prospective buyer about the way the bike rides?

PW: The quick answer is, if you get on that bike you immediately notice it has a nice ride but the bottom bracket is super stiff. People just say, “Wow!”. It is a big difference – a big step forward. There is more to a tri bike than aerodynamics. The best way to understand it is to get on it and ride it.

TK: Sure – did you bring a 61cm with you?

PW: Ha – there is a 61 here, but it’s (pro triathlete) Tom Lowe’s – so if you want to try and wrestle it away from him…

TK: I’ll pass – but beyond the stiffness, have you designed in ride comfort – vertical compliance?

PW: Well certainly we know now that we can use different materials and layups and thicknesses in different areas. So we really tailored the layup and material selection to add ride quality.

TK: The hydraulic brakes are a first on tri bikes. We’ve discussed the aero aspects, but there is more to it than that.

PW: They’re better all around. It’s lighter than Dura-Ace, has more braking power, and better modulation. It’s super easy to adjust the brakes for different wheels. And it is proven technology; used in mountain bikes for years. Every bike shop can service it. And you can even use our aero brake levers with the new Di2 – it allows you to plug in accessory shift buttons which you can mount near the brake levers.

TK: The P5 accepts all currently available wheel designs – correct?

PW: Yup, you can go out to 25mm tires – the trend now is towards fatter tires. The easy way to increase the ride comfort of your bikes is the saddle and the tires. The Cobb and Adamo saddles – that’s a trend because they work. The other way, use a wider rim and tire with lower pressure (e.g., Hed Ardennes or Jets).

TK: How’s the availability on the P5?

PW: Yeah we’ve had some problems there – first we underestimated demand, and then the supply’s been less than we hoped. I think it’ll recover by about January. We’re hammering away at orders pretty good now, but for sure if we had twice as many we’d sell twice as many. And the thing is, we thought there’d be a lot of demand for the P5-3, but most of the customers are triathletes, and they want the latest and fastest, or the P5-6.

TK: You’ve spent as much time in the wind tunnel as anyone, and you’ve also spent a lot of time in Kona. What are some of the biggest mistakes you see athletes making?

PW: The obvious one is stay in the aerobars – get fit properly so you are comfortable and powerful being aero. 85% of your power goes to overcoming aero drag, and the body is 75% of that. After that, put your hydration where you’re going to use it. There is nothing that’s going to slow you down more than having an aero hydration system that you forget to drink from – getting dehydrated and weaving down the road. That’s why I’m a big fan of the horizontal bottle between your arms. Not only is it the most aero position but it’s right there where you will use it. Then there are details. Get rid of stuff hanging off the top tube. Keep the things behind you in tight; narrow and close to your butt. You certainly don’t want to see the bottles from the front. Try to adjust the height between your waistline and bottom of your butt – that’s the sweet spot.

TK: So to wrap it up, the obvious question is where can you go next in bike design?

PW: Well that’s what we pay the engineers for. It is their job to anticipate the un-articulated needs of the customer. We’re not going to do a focus group and ask people what they want, because they don’t know. They’re looking to us to provide that vision – to take them to the next place that will make them happier and faster and loving the experience. Even the fastest bike is no good if you can’t adjust it and you hate riding it or can’t live with it. You look at the P5 now and think everything on that bike is obvious. But of course that is hindsight.

TK: That’s about all I have – thanks very much!

PW: You bet.